Aging hangar doors don't just increase maintenance demands, they disrupt operations, create safety risks, and put revenue at risk.

Across the country, airports and FBOs are choosing Para-Port® to retrofit existing facilities, preserve structures, and restore dependable performance built to serve generations.

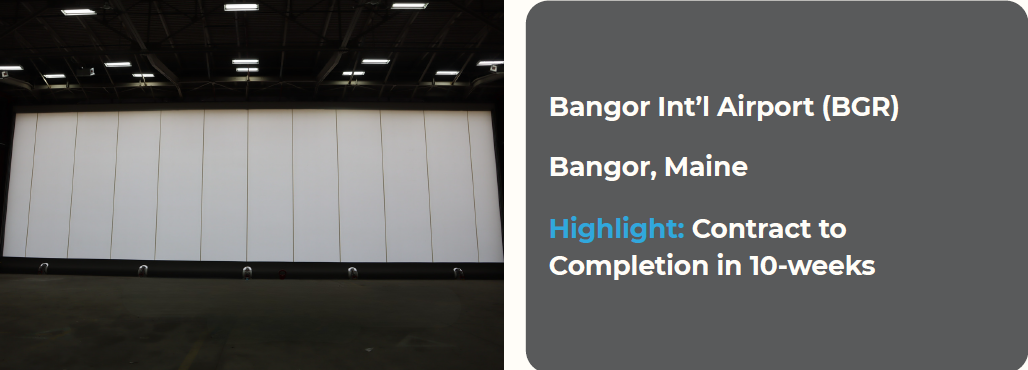

When a hydraulic, cable-lifted steel door failed at Bangor International Airport, a 10,000 sq. ft. hangar was taken out of service almost overnight. With repair contractors unwilling to assume the liability of servicing the damaged door, the airport needed a dependable, long-term replacement that could be installed quickly and perform reliably in Maine’s extreme weather.

Para-Port® Doors provided a retrofit solution that integrated seamlessly into the existing steel structure. The new door eliminated common mechanical failure points, reduced ongoing maintenance exposure, and restored full operations with tight seals and reliable performance in snow, ice, and wind.

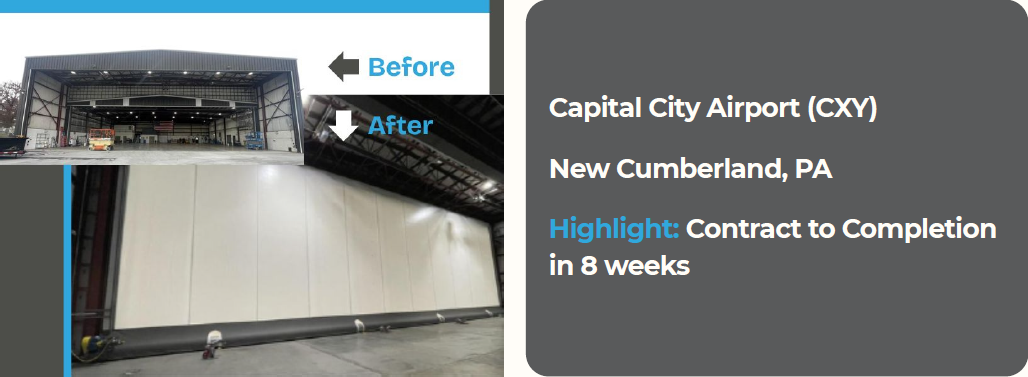

At a corporate aviation facility in Pennsylvania, an aging steel hangar door caused repeated downtime and escalating maintenance costs. Rather than pursue new construction, the company selected Para-Port® to preserve the existing hangar while upgrading to a modern, dependable door system.

A Para-Port® retrofit restored operational reliability, improved energy performance, and delivered predictable daily operation—extending the life of the facility while reducing long-term cost of ownership.

When a bifold door system became unsafe and inoperable at Signature Aviation’s Winston-Salem location, the impact was immediate: a revenue-producing hangar was no longer operational. Already operating more than 50 Para-Port doors across its network, Signature selected Para-Port® once again to retrofit the facility.

The retrofit Para-Port door allowed Signature to quickly recover the hangar with limited additional investment, which delivered consistent operation, reduced maintenance demands, and long-term reliability aligned with the needs of a high-traffic FBO environment.

Why Airports Choose Para-Port® for Retrofit

Questions?

Reach out to our team.

Para-Port® Doors LLC

226 Heritage Drive

Tiffin, OH 44883

Phone: (877) 247-7640

Email: info@Para-Port.com